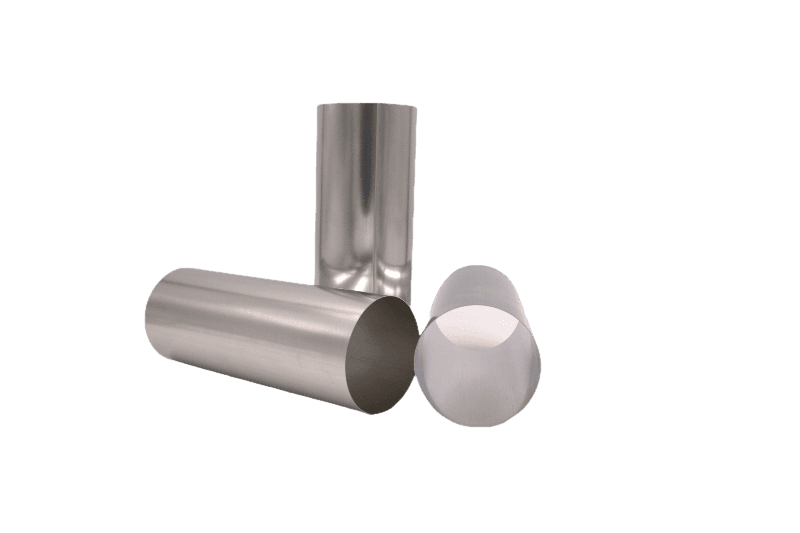

In the realm of modern manufacturing, thin-wall tubing stands out for its exceptional balance of strength, lightweight properties, and versatility. This is especially true in industries demanding high precision and reliability, such as aerospace, energy, and medical devices. Our specialty lies in producing high-quality seamed tubing using advanced manufacturing techniques, ensuring precision, consistency, and reliability in every piece.

Laser Trimming: Precision and Speed

One of the most significant advancements in our production process is the application of laser technologies to cut tubes to length. This state-of-the-art technique allows us to cut tubing quickly and precisely, providing a burr-free finish that is essential for applications requiring smooth and clean edges. The laser trimming process not only enhances the aesthetic appeal of the tubes but also ensures they meet the stringent quality standards necessary for high-performance applications. The accuracy of laser trimming means that every tube is consistent in dimension, an essential factor for maintaining tight tolerances in critical assemblies.

Roll Forming and Welding Process

Our automated roll forming and welding process for thin wall metal tubing is a sophisticated manufacturing technique that combines precision and advanced welding technology. Initially, metal sheets are passed through a series of rollers, progressively shaping them into a tubular form. This rolling process ensures uniformity in the tube’s dimensions, roundness, and maintains the integrity of the thin walls. Once the tube is formed, plasma welding is employed to join the edges. Plasma welding, known for its high energy density and precision, creates a strong, clean, and narrow weld seam, which is crucial for maintaining the tube’s structural integrity and aesthetic appearance.

Custom Lengths and Consistent Dimensions

Understanding the diverse needs of our clients, we offer thin wall metal tubing in custom lengths and dimensions, and shapes. Whether you require tubing for medical devices, aerospace components, or industrial machinery, we can tailor our products to meet your specific requirements. The consistency in dimensions we provide is unmatched, ensuring that each piece fits perfectly into your assembly, reducing the need for adjustments and rework. We can produce lengths of up to 20 feet. No unique tooling or fixtures which helps lower costs.

Versatile Material Options

The materials used for ultra-thin tubing must possess excellent mechanical properties to withstand the demanding conditions of their applications. Common materials include:

- Stainless steel: known for its corrosion resistance and strength

- Inconel, which offers exceptional heat resistance

- Monel, prized for its toughness and resistance to corrosive environments

- Hastelloy, which provides outstanding performance in extreme conditions

Conclusion

Our thin wall metal tubing represents the pinnacle of precision engineering. The advancements in automated tube mill technology and thin wall tube welding have paved the way for the widespread use of thin-wall tubing across various high-stakes industries. As these technologies continue to evolve, the possibilities for even more precise and high-performance applications of thin-wall tubing are boundless, pushing the limits of what is possible in engineering and design. Whether you need custom lengths or specific material properties, our tubing solutions are designed to deliver excellence in every application. To learn more, visit our page about Thin-Wall Metal Tubing.