Product Assemblies and Kits

Full-Service Product

Design Partner

Integrated Services Minimize Product Lead Times

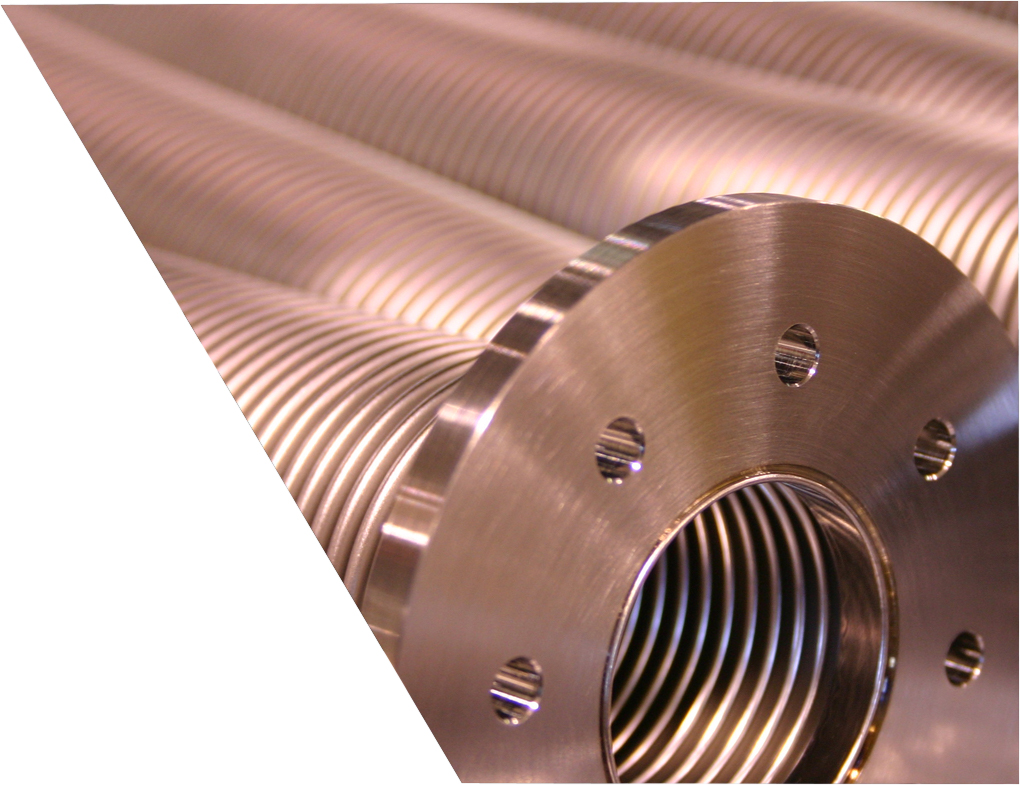

Leading manufacturers expect their supply chain partners to understand their business and provide value to their operations. Our proven end-to-end systems and processes create turnkey solutions that help customers focus on their core competencies. Our in-house team of welding, process machining and design engineers can model full product solutions using SolidWords 3D modeling, CNC programming in GibbsCAM, as well as application and lab testing. From concepts to drawings, we can make or assemble full kits in-house.

We utilize proven project management methods for new product development, including a dedicated team that is built around your custom needs. We also follow a stage gate process that accelerates the development from concept through production.

Beyond world-class machining and manufacturing, we offer a number of essential value-added services designed to help you meet virtually any request from your customers.

Alloy Precision Technologies continually re-invests in our equipment, facilities, software and people to help you win, no matter what your requirements may be. These include:

- Management of Bill of Materials and related inventories and secure stock room

- JIT inventory solutions

- Rapid response prototyping capabilities

- Long-term service agreements & stocking programs

- Kit testing including quality, performance and sampling

- Shipping, packaging and branded labeling of full kits to end users