Ultra Thin-Wall Tubing

Alloy Precision Technologies Ultra-Thin Wall Tubing

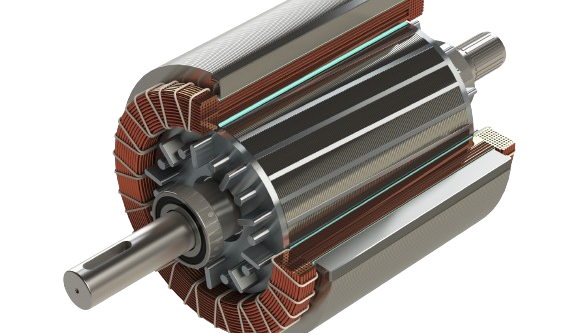

At Alloy Precision Technologies, we pride ourselves on being an industry leader in Ultra-Thin Wall Tubing. Our advanced manufacturing processes ensure that each tube we produce is of the highest quality, offering exceptional durability, and precision. Our custom seamed thin wall tubing is ideal for applications requiring strength without bulk. We understand that one size does not fit all. That’s why we offer custom lengths and sizes tailored to your unique specifications. Our thin wall tubing is engineered for versatility and reliability, making it ideal for a wide range of industries and applications. Whether you need lightweight components for electric motor liners or high-performance solutions for complex assemblies, our thin wall tubing delivers unmatched quality and performance across industries.

Custom Lengths & Sizes

At Alloy Precision Technologies, we utilize state-of-art manufacturing processes, enabling us to have control over wall thickness and diameter, while efficiently meeting our customers’ specifications. Whether you need long continuous lengths or precise short segments, we’ve got you covered. Our customers’ have unique applications requiring custom lengths. Our capabilities include:

High Quality Thin Wall Tubing Materials

Our thin wall tubing is crafted from a variety of premium alloys, ensuring that we can meet the specific needs of your project. Each material is carefully selected to provide optimal strength, corrosion resistance, and lasting performance, ensuring that our tubing meets your exact specifications and application needs. Typical material types include:

Other Key Capabilities

At Alloy Precision Technologies we leverage our precision laser trimming process and automated tube mill processes to produce durable metal thin wall tubing. Our state-of-the-art laser trimming technology ensures precise cuts and minimal material waste, enhancing the quality and consistency of each tube. Coupled with our automated tube mill, allowing for us to deliver high-volume production without compromising quality.

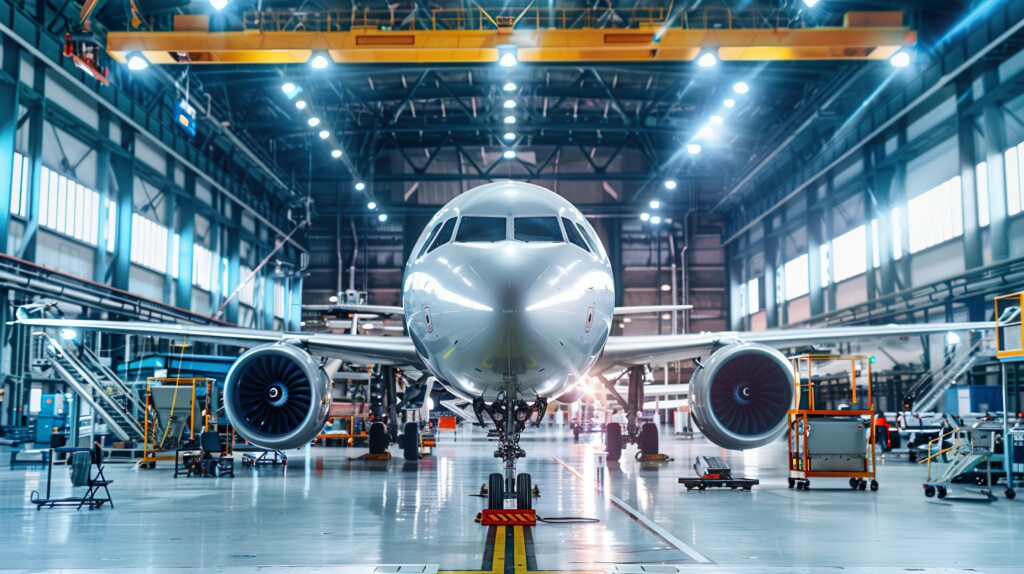

Industries & Applications

Alloy Precision Technologies’ thin wall tubing plays a crucial role in a broad range of industries and applications requiring precision and durability. Typical applications include but not limited to fluid transfer lines, motor stator/rotor liners, instrumentations wiring covers, heat transfer tubing, and more.