Advanced Welding Capabilities

To meet the rigorous durability and precision standards required by industries like aerospace, power generation, petrochemical, and medical, manufacturers face complex welding challenges. These often include joining dissimilar or exotic metals and handling ultra-thin-walled materials. Alloy Precision Technologies addresses these challenges with advanced welding processes, ensuring assemblies that meet the exacting demands of each application.

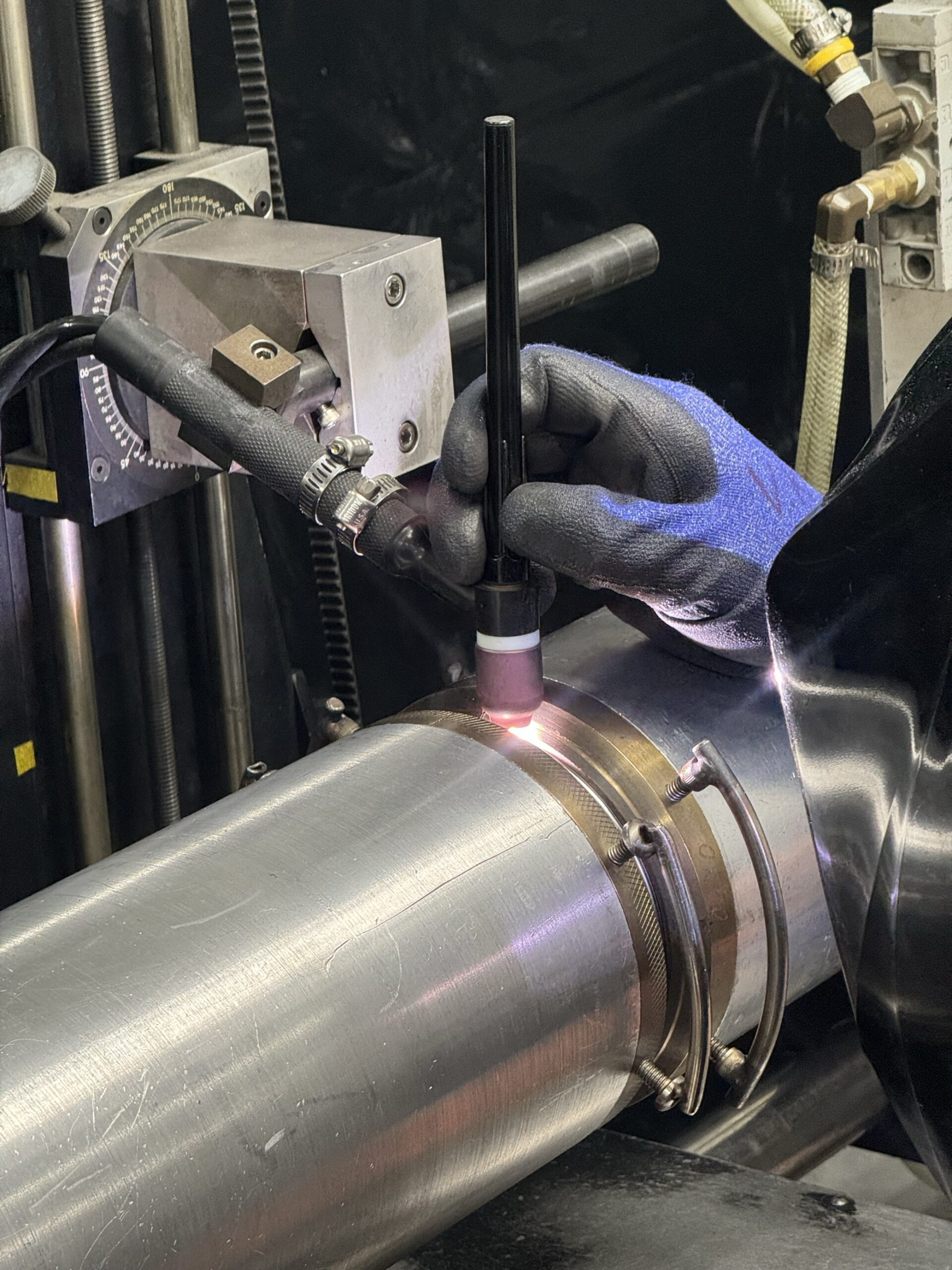

Precision Welding Process

Our proprietary welding process is designed to produce controlled welds with minimal visibility and superior strength. These welds achieve tight dimensional tolerances, resulting in longer-lasting products even in demanding environments. With both fully- and semi-automated processes, we control every aspect of the welding, from the workpiece handling to the heat source, guaranteeing precision on every weld.

Tight Tolerance Specifications

- Tolerances as precise as +/- .003” in length

- Angular accuracy within 1⁄2 degree

- Welded seams as thin as .020”

Precision Welding Capabilities:

- Fully and semi-automated processes for consistent quality

- TIG, PAW (Plasma arc welding), and Laser welding capabilities

- Specialized experience with ultra-thin and dissimilar metals

- Controlled processes to meet tight dimensional tolerances

- Chamber welding for contamination-free, high-purity results

Certifications

Alloy Precision Technologies brings industry-leading expertise and certifications to every welding project. Our team includes highly skilled welders, each certified to ASME IX and AWS D17.1 standards. We are also NADCAP certified for both NDT (Non-Destructive Testing) and welding, ensuring the highest quality and reliability for critical applications.

Soldering & Brazing Capabilities

Beyond welding, Alloy Precision Technologies also offers expert soldering and brazing services. Many industries, such as aerospace and instrumentation & control, require high-quality soldered and brazed assemblies for bellows, machined parts, and other components. Our dedicated solder and braze work cells enable single-part flow, often providing a convenient one-stop solution for customers with custom product needs.

Available Materials