Renewable Energy

Transforming the Supply Chain

for Renewable Energy

Full Integrated Services Enable Superior Performance

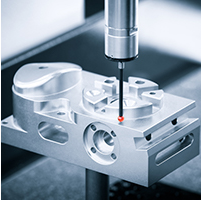

Our vertical integration features a team of design, machining, welding, and manufacturing engineers who have decades of experience in creating new products. We manufacture bellows, machined products, and welded solutions to help improve the performance and durability of their renewable energy operations.

We continually invest in the tools and technologies necessary for world-class product development and precision manufacturing. Our full-service approach includes state-of-the-art, proprietary software for modeling, rapid prototyping, testing, custom tooling, and manufacturing.

In addition, our custom soldering and brazing capabilities feature automated work cells, project-specific tooling, and testing equipment designed for small, precise components. Our dedicated single piece workflow stations allow for customized products with a separate area for custom quality testing including pressure testing, altitude testing, and overall performance testing.

Our in-house NDT level 1, 2, and 3 inspectors conduct performance and cycle testing in each stage of the production process to certify quality and durability. Specific tests include:

- X-Ray testing

- Fluorescent Penetrant Inspection (FPI)

- Visual inspection

- Performance testing

- Helium mass spectrometry to 1 x 109 cc/second.

- Pressure testing

Our bellow assemblies and other products can be used in many renewable energy applications, including:

- Exhaust bellows

- Exhaust manifolds

- Reformers

- Flexible expansion tubing & joints

- Ultra-thin-wall tubing

- Flanges

- Manifolds

- Instrumentation & control systems