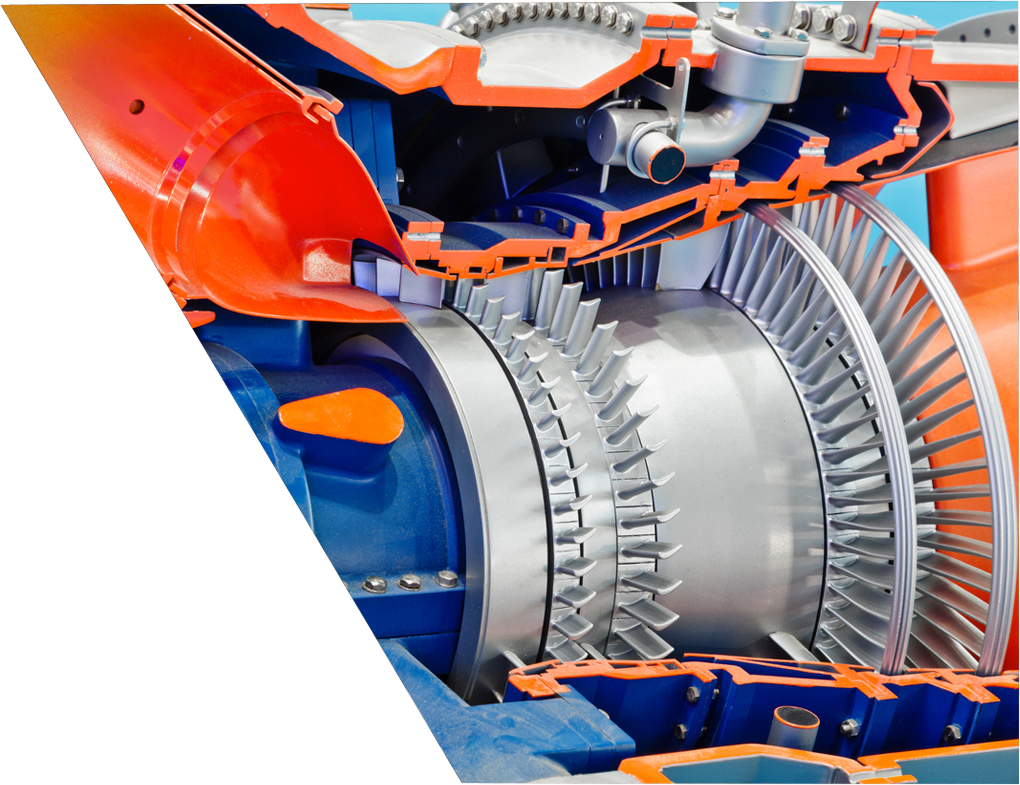

Power Generation

Power Generation Relies

on High Efficiency Components

Our welded metal bellows assemblies provide flexible, dynamic seals capable of operating in extreme environments while providing zero leakage and high cycle life. To extend the service life of our customers’ equipment, Alloy Precision Technologies utilizes a range of high-temperature materials matched with years of experience manufacturing high tolerance assemblies. These require a precision manufacturing process utilizing state-of-the-art equipment for forming, welding, brazing, soldering, bending, and machining of the finished assembly.

As a vertically integrated partner, leading manufacturers collaborate with our in-house team of engineering design, manufacturing, welding, and machining experts to ensure seamless project execution. Our equipment, tooling, and fixturing ensure your components and assemblies are machined to exact tolerances and specifications. As an ISO 9001:2015 company, our certified quality assurance and testing programs guarantee the highest standards for our finished components and assemblies.

As a vertically integrated partner, leading manufacturers collaborate with our in-house team of engineering design, manufacturing, welding, and machining experts to ensure seamless project execution. Our equipment, tooling, and fixturing ensure your components and assemblies are machined to exact tolerances and specifications. As an ISO 9001:2015 company, our certified quality assurance and testing programs guarantee the highest standards for our finished components and assemblies.

Beyond sophisticated machining and manufacturing, we offer a number of essential value-added services designed to help you meet virtually any request from your customers. These include:

- Rapid response prototyping

- JIT and strategic stocking programs

- Full product assemblies including design, manufacturing, testing, and packaging

Our products and assemblies can be used in many power generation applications, including:

- Fuel nozzles, fuel injection components

- Flexible metal seals/ducts

- Flexible metal tubing

- Combustion components

- Precision Weldments

- Instrumentation & control assemblies

- Hydraulic manifolds