Aerospace

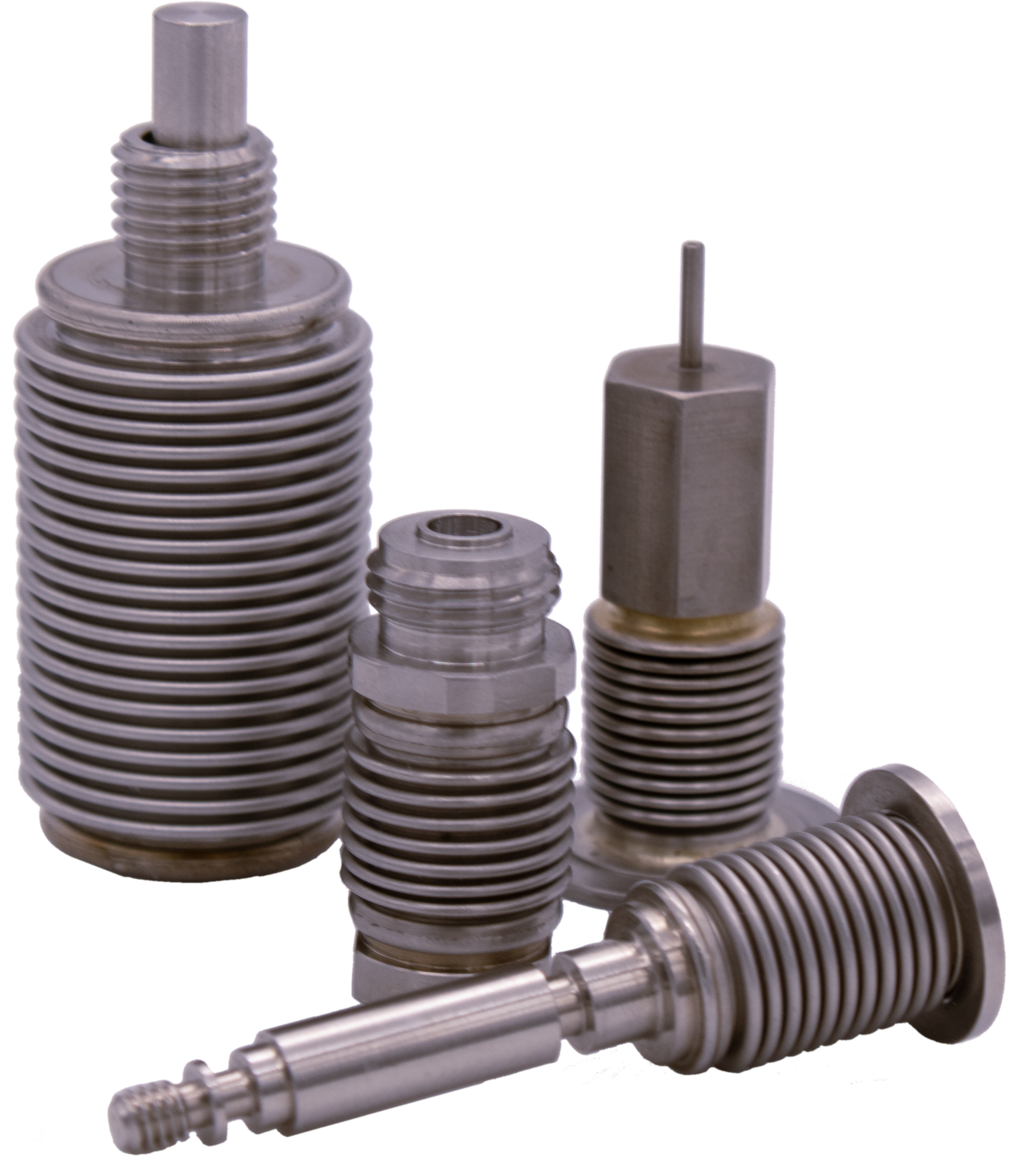

Alloy Precision Technologies’ Aerospace & Defense Solutions

At Alloy Precision Technologies, we have pioneered the design and manufacture of metal bellows and highly engineered assemblies, for the Aerospace and Defense industries. We are committed to enhancing the performance and longevity of critical parts and assemblies used in the Aerospace and Defense sectors. Our solutions are engineered to maximize cycle life, reduce maintenance needs, and lower overall costs while meeting the most demanding application requirements. From managing extreme temperatures and cycle times to ensuring precise motion control and reliable performance under high vibration conditions, our products are designed for rigorous environments, including high-altitude pressure control and temperature regulation.

Application of Metal Bellows in Aerospace & Aircraft Systems

Metal bellows are integral components in various aircraft systems, such as actuators, fuel systems, and environmental control systems. They serve as flexible connectors in areas requiring movement or vibration absorption, including engine and landing gear systems. Additionally, metal bellows can function as pressure sensors or as components in aneroid valves for fluid control.

Certifications & Compliance

Alloy understands that the reliability of every aircraft hinges on the quality of individual components. Each manufactured part undergoes rigorous testing and adheres to the highest industry standards to ensure that we meet our customers needs.

Credentials:

- NADCAP NDT

- NADCAP Welding

- AS9100 Rev. D

- ISO 9001:2015

- DFARS Compliant

- ITAR

- CMMC 2.0 Level 3