Precision Welding

Advanced Capabilities

Certified Welders

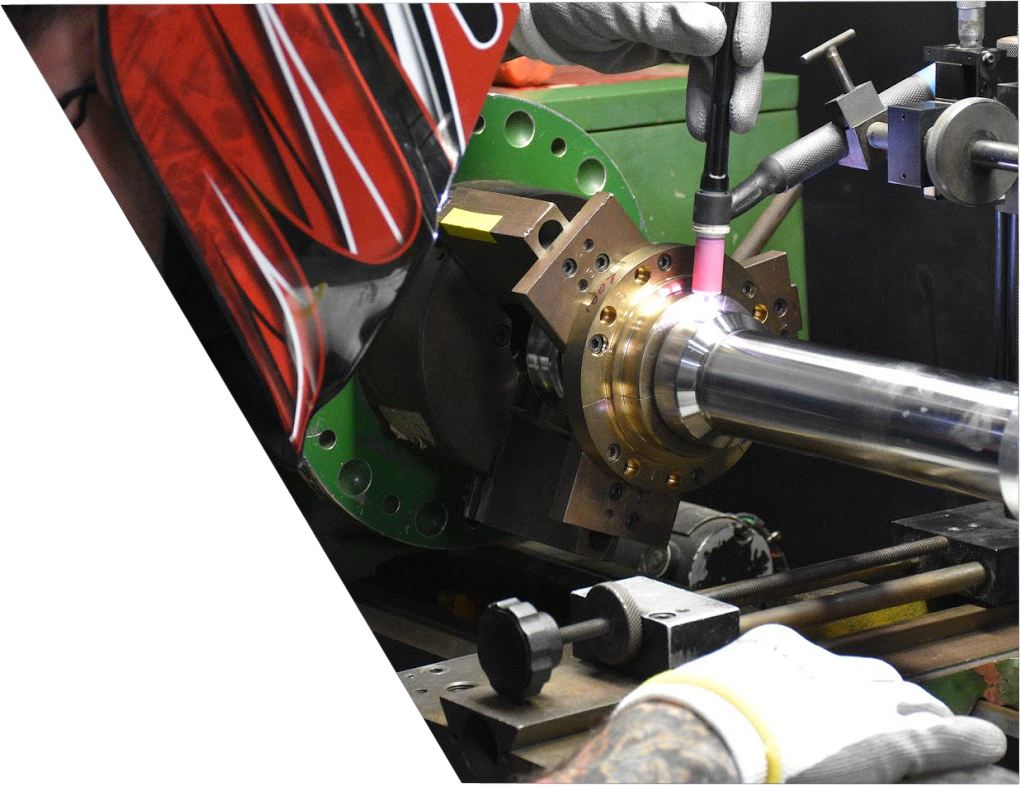

Our proprietary process produces controlled welds with barely visible lines that achieve tight dimensional tolerances. As a result, our welded products have a longer product service life even in demanding applications and environments.

360-degree work cells, and fully- and semi-automated processes control the work piece and manage the welding heat source to deliver precise results every time. We can achieve tolerances as tight as +/- .003” in length, within 1⁄2 degree of angularity, and with welded seams as thin as .020”.

Certifications

ASME Section IX

European PED

EN1418

MIL-STD-1595A

Alloy Precision Technology’s Precision Welding Capabilities & certifications:

Alloy Precision Technology’s Precision Welding Capabilities & certifications:

- Fully & semi-automated processes

- TIG & laser welding

- Expertise in ultra-thin metal & dissimilar metal joining

- Process control for tight dimensional tolerances

- All welders individually ASME IX certified.

- Chamber welding (contamination-free, high purity welding)

Alloy Precision Technology’s Soldering & Brazing Capabilities

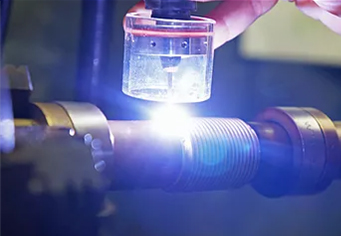

It isn’t enough to be able to produce bellows, machined parts, and be able to weld them together. Some applications require tighter tolerances than welding can offer. Many industries, including aerospace and instrumentation & control require high quality solder & braze of bellows assemblies, machined parts, and more.

For this, Alloy Precision Technologies has dedicated solder & braze work cells for single part flow. For many of our customers, this area becomes a one-stop-shop for their custom products. Here, we not only solder & braze our customers’ products & equipment, but this is also the center for product testing, including:

- Performance testing

- Helium leak & pressure testing

- Altitude & calibration testing

- Carbon steel

- Stainless steel

- Aluminum

- Inconel

- Monel

- Titanium

- Hastelloy

- Brass

- Beryllium Copper

Quality Guaranteed

To ensure the quality of your products, Alloy Precision Technologies has in-house nondestructive testing and certified inspection capabilities. Along with our soldering & brazing specific testing, our quality assurance process includes metrology analytics and testing using X-ray, OFP, NDT, and Nitrogen and Helium testing.